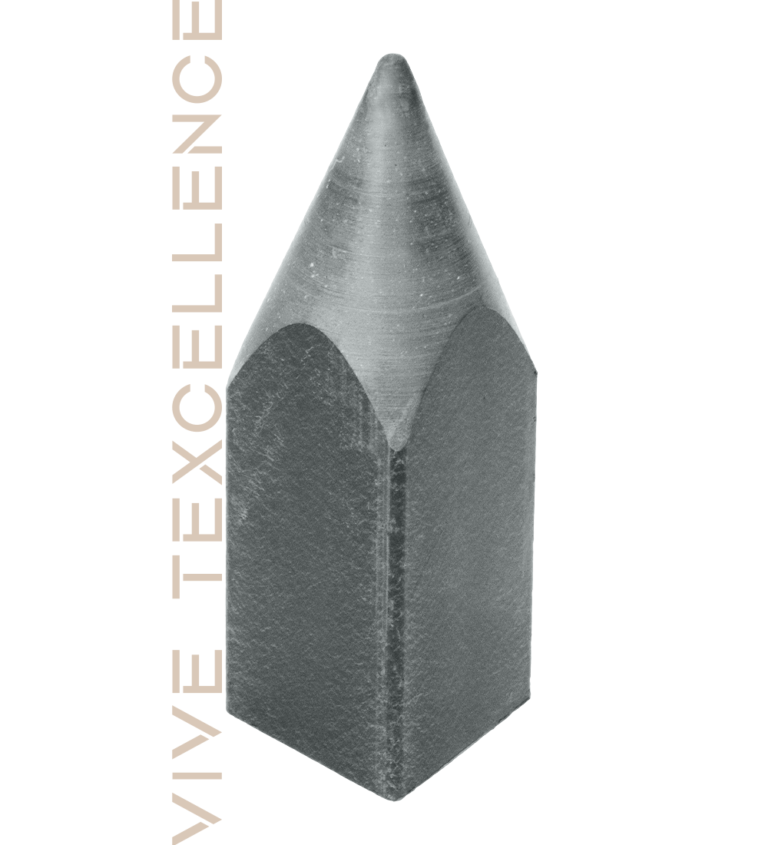

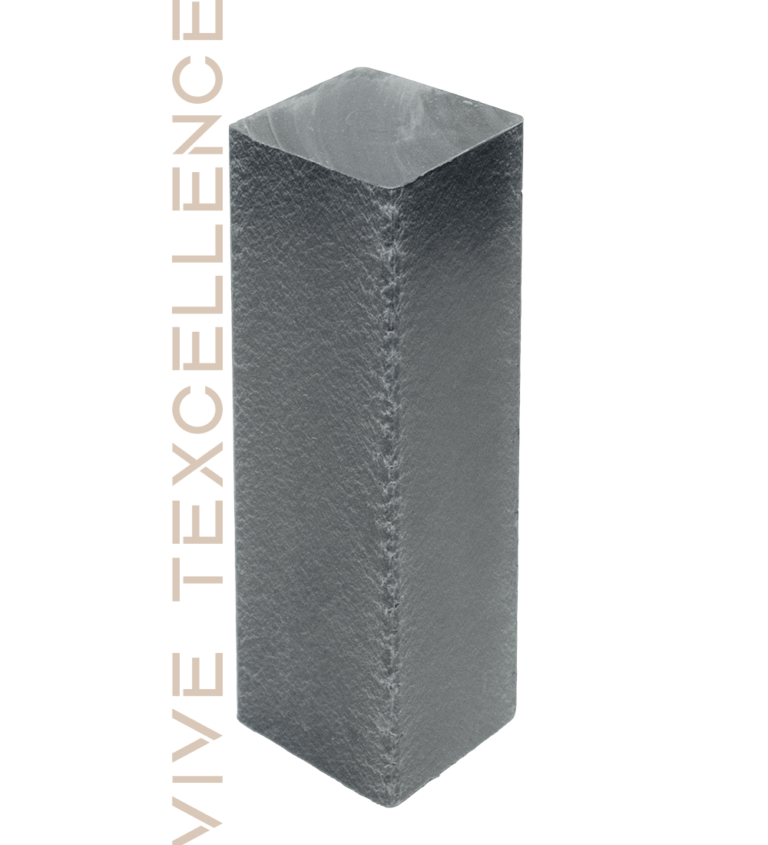

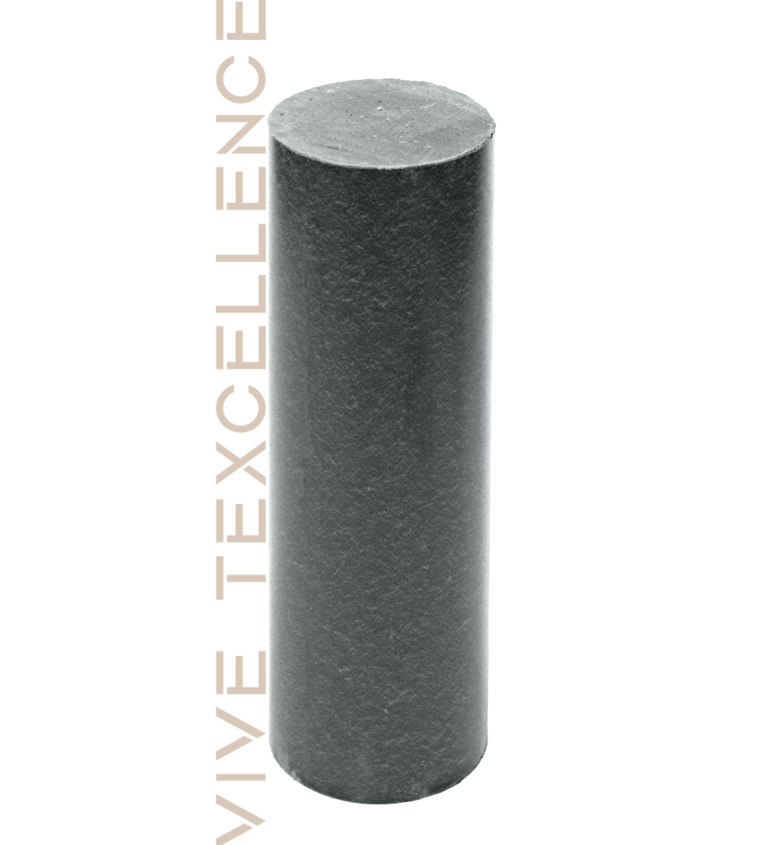

VIVE Texcellence

VIVE Texcellence is a composite made from a combination of used textiles and plastic waste. The textile fibers act as reinforcement inside the profile structure making it much stiffer than plastic profiles.

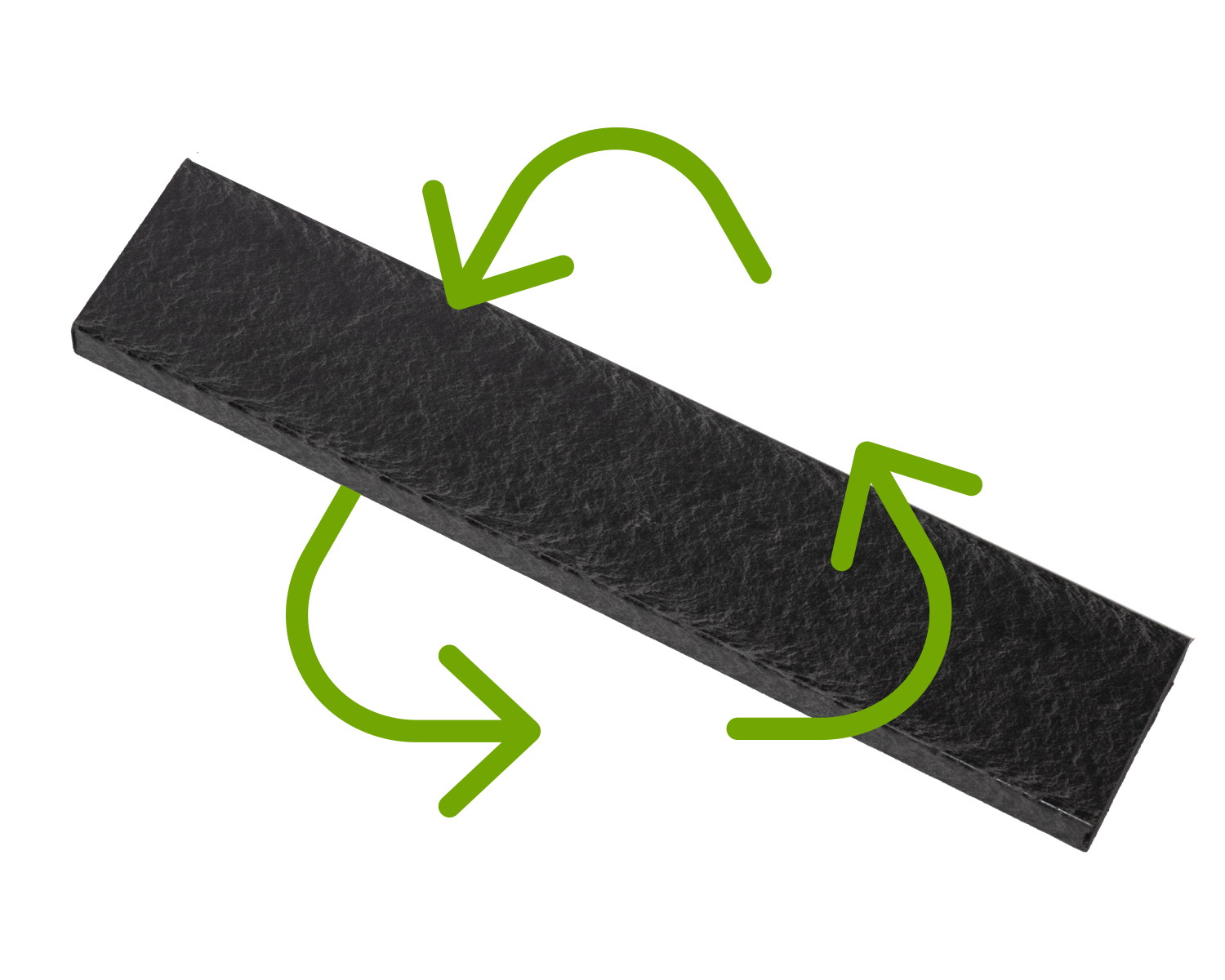

The base composite is made from 100% recycled raw materials, and one of its most important features is that it can be 100% reused at the end of its life cycle.